In this video, we’ll teach you everything you need to know about the Ultra-Spill Deck – Fluorinated models, designed to be more compatible with aggressive chemicals and chlorinated solvents. Note that our training videos are mostly designed to help our distributors better understand our products but can also be helpful to users of the products, as well.

TRANSCRIPT:

Hello, and welcome to another UltraTech product training session. Today, we are talking about the Ultra-Spill Deck Fluorinated Models. UltraTech has a number of rotationally molded spill containment decks. The majority of them are made with polyethylene, but the fluorinated model takes it one step further. Where we use those same rotationally, molded polyethylene spill decks, but put them through a fluorination process which enables them to be more compatible with aggressive chemicals and chlorinated solvents.

Here’s our chemical compatibility guide for polyethylene. You can see there’s a number of different chemicals that you can check to see if they are compatible with our standard spill decks, a closer look shows that each chemical has a rating of A, B, or C.

A is suitable for long-term storage, B is suitable for short-term storage, and C is not recommended for use with UltraTech spill containment products. So the rule of thumb with fluorinated spill decks is that you can take those ratings and upgrade them by one letter. So if you look at the top of that list, carbon bisulfide is rated a C. That’s for standard polyethylene. With a fluorinated spill deck, it would be a B.

Now I stress that that is a rule of thumb and that any ratings be double-checked by our engineering staff at UltraTech. So please contact us if there are any questions if it’s not specifically called out in our compatibility guides and we will let you know for sure.

In addition to the standard polyethylene chemical compatibility. We also have one specific to the fluorinated spill decks and spill pallets. So you can look those up. You can see it’s the same type of system where we rate it as an A, B, or C. It’s not as lengthy or as exhaustive of a list as the standard polyethylene, but we do have some of them listed so you won’t have to contact us. And you’ll be able to look that up for yourself.

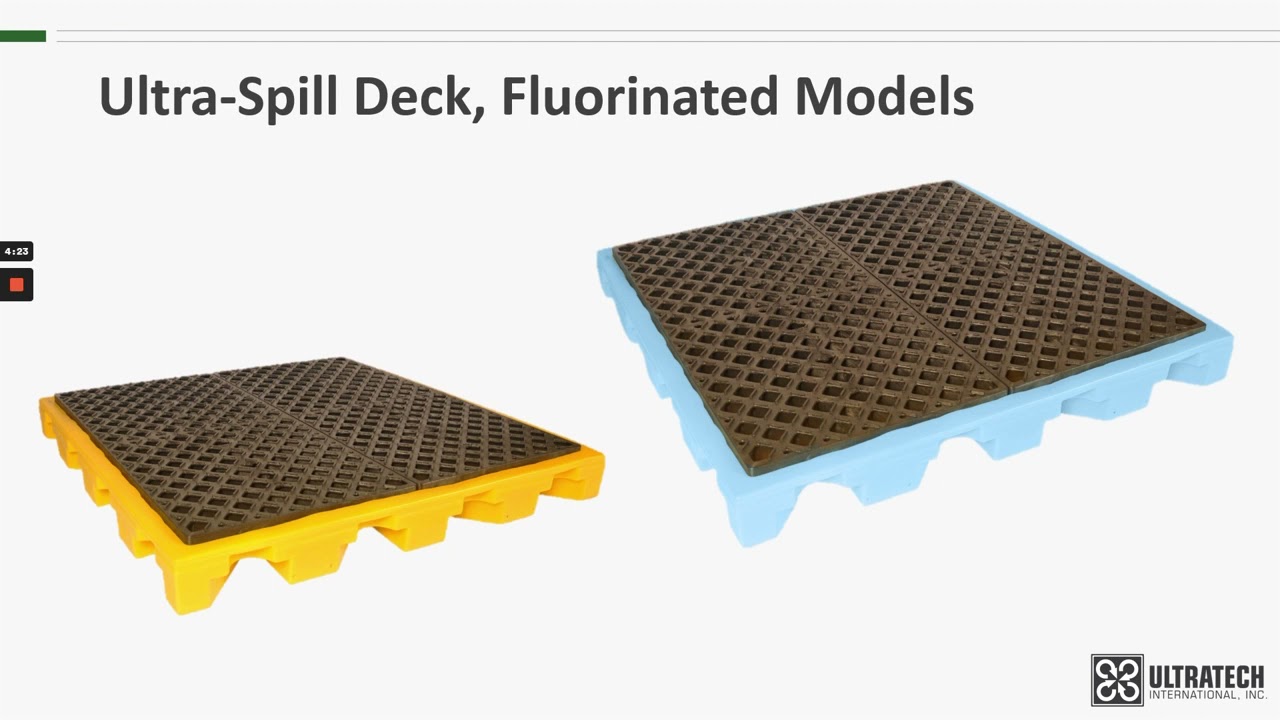

If you look at the fluorinated spill decks closely in this slide, you can tell that we do use the same molds to make these as we use for the standard spill decks. Dimensionally, length, width, height, containment, capacity, weight capacity it’s all the same as the standard spill deck. And the same thing applies for the two drum model. It uses the same mold as the standard two drum spill deck. Again, length, width, height, containment, capacity, weight capacity is all the same. We simply use a light blue resin when we make the fluorinated models instead of the yellow resin that we use for the standard model.

As far as specifications for the fluorinated model spill decks weight capacity, the one drum holds up to 1,500 lbs, the two drum holds up to 3000 pounds. And the four drum holds up to 6,000 pounds. That is uniformly distributed load.

The containment capacity is 11 gallons for the 1-drum, 22 gallons for the 2-drum, and 44 gallons for 4-drum. It’s important to take note of these capacities because, by themselves, these decks will not comply with EPA and SPCC spill containment regulations. However, the spill decks are designed to be connected together in order to share containment capacity and therefore meet the regulations. For more information on how the spill decks can be connected please take a look at our standard spill deck video. I will include a link in the description below.

I will also put a link down below to a video that helps to explain the EPA regulations in further detail.

They are made with one hundred percent polyethylene that’s fluorinated, of course. It is a modular system so you can connect as many decks as needed and that system or platform could include any combination of 1, 2, and 4-drum decks.

Applications for the fluorinated model spill decks will, of course, be more than likely something to do with the chlorinated solvents or aggressive chemicals that they are designed to work with. It’s more than likely going to be an indoor application. And that could be in manufacturing, warehousing, chemical processing, property management, auto service, any number of industries where 55-gallon drums of chlorinated solvents or aggressive chemicals are used.

Why would you choose the fluorinated model over one of our other model spill decks? I think that one’s pretty easy. Probably the only reason you would choose it is because of the enhanced chemical compatibility that the fluorination process adds.

Why wouldn’t you use it? They are relatively expensive. The fluorination process adds considerable cost to them. So unless you have compatibility issues, the standard spill deck is probably the better solution.

Other products to consider if you’re looking at fluorinated spill decks and aren’t quite convinced? We have fluorinated spill pallets which have the same compatibility but are stand-alone units that don’t require them to be connected. They’re also forkliftable so they have better portability.

We also have, of course, the standard spill decks so if chemical compatibility is not an issue, those are an excellent choice.

And there’s also the spill deck bladder systems that provide the low profile of the standard spill decks but use a hidden bladder to meet the spill containment regulations.

I will include links down below to all of these products should you want to take a closer look.

Thank you for your time. Look for more product training videos on our YouTube channel.