The Advantages of Rotomolding

UltraTech spill containment products are manufactured using a process known as rotational molding or rotomolding. While there are other processes that can (and are) used to make similar products, there are a number of reasons why our method is better:

- Consistent wall thickness: The constant rotation of the mold coats the walls evenly during both the heating and cooling processes

- High durability: Parts are molded as one solid piece, eliminating the need for joining techniques such as welding and joint fabrication which creates weak spots

- High stability: The molding material isn’t exposed to external pressure, increasing its stability and reducing the risk of defects in the finished part

- High strength: Rotomolding creates thicker corners, reducing the risk of failure in these stress-concentration points

For these reasons as well as our commitment to our customers to provide world-class products & solutions and an exceptional customer experience we proudly offer the industry’s best warranty.

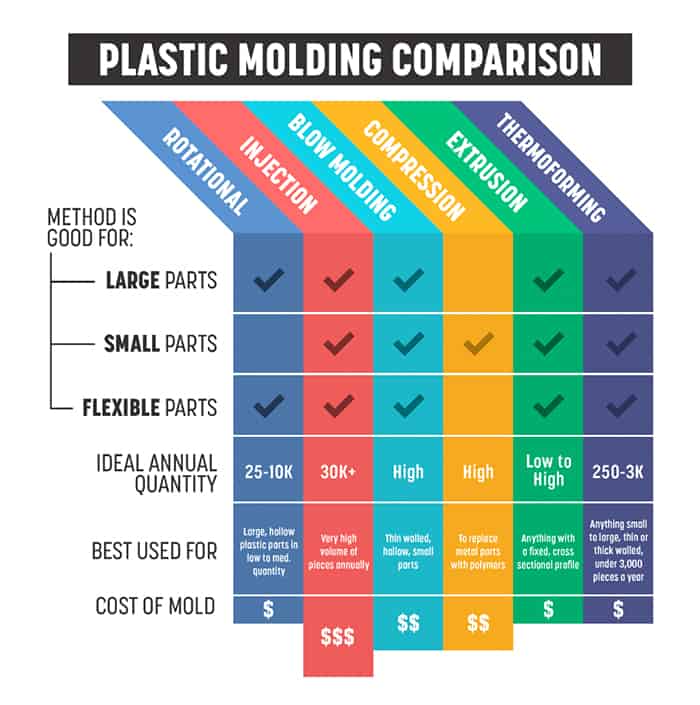

This infographic shows different types of plastic molding and the advantages/strengths of each: