Capture hazardous spills from railroad tanker cars

Ultra-Track Pans have been designed to provide railroad spill containment at industrial rail sidings and locomotive maintenance facilities. The modular design can be used for spill control for everything from small drips during maintenance to catastrophic spills from tanker cars.

Ultra-Track Pans have been designed to provide railroad spill containment at industrial rail sidings and locomotive maintenance facilities. The modular design can be used for spill control for everything from small drips during maintenance to catastrophic spills from tanker cars.

Product Highlights

- Ultra-Track Pans may be used to collect small spills and leaks OR to capture and channel off significant spills caused by defective equipment or a major overflow.

- Long work life - estimated to perform 20-30 years.

- Modular design - center and side pans are 53.5" long; railroad spill containment areas can be easily assembled to any length desired

- All-polyethylene construction - rugged track pans withstand harsh chemicals and are designed to function in temperatures ranging from -40°F to +140°F.

- Sealed system - polyethylene (LLDPE) gaskets keep spills from falling between the rails and pans.

- Below grade piping - all center and side track pans are molded with pipe fitting locators at their lowest point. Below grade piping can be installed to channel large spills to oil/water separators, holding ponds, etc.

- Low maintenance - unlike carbon steel track pans, Ultra-Track Pans will not rust or corrode. Polyethylene resin is treated with a UV inhibitor, resists degrading effects of the sun.

- Low cost installation — lightweight track pans can be easily installed without heavy lifting equipment, i.e., forklifts, cranes, backhoes, etc. Minimal tools and labor required.

- Slip resistant surfaces - pans and grates have been designed with safety in mind. All top surfaces resist slips when wet or oily.

Advantages of Ultra-Track Pans vs Competitive Products

- Easy Installation: Lightweight, smaller pans are very easy to move around and install without heavy equipment

- Chemical Resistance: Polyethylene construction has excellent chemical resistance – better than metal and other materials.

- Patented Gasket System: Seals against the rail eliminating a potentially large leak point.

- Grating is Included: All Ultra-Track Pans come with grates as part of the design/integrity for walking on or setting up drive over points. Personnel do not have to walk in spilled product in pans due to grating in every pan, reducing liability.

- Modular: If something gets damaged, only a small section will need to be replaced.

- Patented Horizontal Flow: Flow-through channels and bulkhead fittings allow spills to travel from pan to pan. Track pans, of all kinds, have limited capacity, so routing a spill sideways and then through below-grade piping is very critical.

- Multiple Drain Capacity: Ultra-Track Pans are designed so they can accommodate multiple drains in as many pans sections as desired.

- Crude Oil Applications: Viton gaskets available for installations in crude oil loading/off-loading areas.

- Longevity: Estimated 20-30 year work life.

NOTE: Unless otherwise noted, all listed product measurements are L x W x H, outside dimensions, and for a single unit where quantity is more than one.

| Part # | Model | Dimensions in. (mm) | Containment Capacity gal. (L) | Weight lbs. (kg) | Quantity |

|---|---|---|---|---|---|

| 9566 | Center Pan with Grates | 53.5 x 53.5 x 6 (1358.9 x 1358.9 x 152.4) | 18 (68.1) | 112 (50.8) | 2 bulkhead fittings, 4 gaskets and 2 grates |

| 9576 | Side Pan with Grates | 53.5 x 27.5 x 6 (1358.9 x 698.5 x 152.4) | 19 (71.9) | 58 (26.3) | 1 bulkhead fitting, 2 gaskets and 1 grate |

| 9598 | Center Pan with Grates - INTERNATIONAL | 53 x 42.75 x 4.39 (1346 x 1086 x 111) | 14.75 (55.8) | 39 (17.7) | Please Contact Us. |

Frequently Asked Questions

-

120 gallons-per-minute (gpm).

-

Under normal working conditions, the Ultra-Track Pan system should last from 20 to 30 years in the field. Due to rugged conditions expected at rail sidings, Ultra-Track Pans are molded in nearly twice the thickness of standard containment products manufactured by UltraTech. The black color, combined with an ultraviolet (UV) ray inhibitor added to the polyethylene (LLDPE) resin, helps protect the system from harmful effects of the sun.

-

Without grates, each center track pan holds 30 gallons and each side track pan holds 25 gallons. Each track pan grate displaces 6 gallons of fluid. Therefore, each center track pan with grates holds 18 gallons and each side track pan with grates holds 19 gallons.

Ultra-Track Pans are connected together with bulkhead fittings. One (1) bulkhead fitting is used to connect each side track pan “end to end” and two (2) bulkhead fittings are used to connect each center track pan “end to end.” The patented bulkhead fitting design allows spilled fluids to travel from one pan to the next, thereby increasing capacity as the spill travels over the length of the Ultra-Track Pan system.

-

Ultra-Track Pans are virtually maintenance-free. Visual inspection of the sealing gaskets located between the rails and pans should take place every six (6) months.

-

The gaskets that seal between the pans and tracks are closed-cell polyethylene (LLDPE) foam. The closed-cell material will not soak up any fluid.

-

All of these items are made of polyethylene. Coupled with the polyethylene (LLDPE) track gaskets, the Ultra-Track Pan product line offers consistent chemical compatibility.

Note: Standard gaskets for the bulkhead fittings are EPDM—other materials are available if necessary.

-

The all-polyethylene Ultra-Track Pans offer excellent chemical resistance for a broad range of acids, caustics, corrosives, solvent, oils, diesel fuel, etc. UltraTech’s engineering staff is available to review specific chemicals upon request.

-

All top surfaces of the major Ultra-Track Pan components feature a slip-resistant design. Grates have a raised, molded-in texture that is very similar to a diamond plate design. The inner surface of all center and side track pans has a surface that is similar to 80-grit sandpaper.

-

-40° F up to + 140° F.

-

No effect.

-

Metal rake, shovel, sledgehammer, two 12” bar clamps, two pieces of wood 1” x 4” x 48”, two “slip sheets” approx. 10” x 60”, and a utility knife are typically required.

No heavy equipment required.

-

No. Gaskets and bulkhead fittings are standard components and are packaged inside each Ultra-Track Pan shipping container.

Note: If planning to install below grade piping, 3” diameter bulkhead fittings to connect to piping must be ordered separately.

-

Each Ultra-Track Pan is boxed separately to assure they are protected properly during shipment. The modular units stack neatly on wooden shipping pallets via LTL or full truckload shipments, depending on the size of the order.

-

Yes. Center pans and side pans have molded-in recesses at their low points. The recesses are shaped like large “hockey pucks” and can easily be drilled out for 3” diameter polyethylene (LLDPE) bulkhead fittings. (Click here to see pictures of a below-grade piping installation.)

-

The location and spacing of railroad ties along a set of rails are not entirely predictable. We have provided multiple pipe recesses to guarantee that at least one recess can be used for piping without disturbing any ties.

-

No. The pipe recesses give you the option to do so if desired. Many users are concerned only with capturing small spills and leaks and do not have the desire or need to pipe below grade.

-

Yes. The modular design of the Ultra-Track Pans allows them to follow along a curved track up to 12 degrees.

-

(Note: Rail weight is defined as the number of pounds per yard of rail length.)

Ultra-Track Pans have been successfully installed on rails as light as 65 lb. All rails greater than 65 lb. work very well with Ultra-Track Pans. Rails that are less than 65 lbs. are not feasible as the rails are too short to allow proper clearance. -

Yes. Please click here to download a worksheet that details a cutaway of a standard rail and tie plate. We will need all of the information in order to determine the correct gasket design that the installation will require. If your installation location has pandrols, we will also need the information on the second page of the worksheet.

-

Railroad tanker cars typically range from 35 – 60 feet. Each Ultra-Track Pan is 53.5” (4 ½ nominal feet) long and can be configured to virtually any length desired.

Locomotives typically require a 60-foot track pan system. -

Yes, provided the following:

- Track pan grates are in place in each pan.

- Adequate support (i.e. compacted soil) is provided under each pan.

- If side pans are installed, concrete must be poured to “ramp up” to the outer sidewalls of the side pans.

Note: Vehicle weight limitation of the Ultra-Track Pan is dependent on the strength of the bedding material under the pans. UltraTech engineers are available to provide guidance in specifying bedding material, etc.

More Info / Downloads

Helps Comply with These Rules & Regulations

- EPA Container Storage Regulation 40 CFR 264.175

- Spill Prevention, Control and Countermeasure Act (SPCC) 40 CFR 112

- Stormwater Management Regulation 40 CFR 122.26

- New York State Chemical Bulk Storage Regulation Section 599.17c

Additional Product Information

Uniform Product Codes (UPCs)

- UPC 808416095661 Ultra-Track Pan Center Pan with Grates (Part #9566)

- UPC 808416095760 Ultra-Track Pan Side Pan with Grates (Part #9576)

- UPC Center Track Pan with Grates - INTERNATIONAL Center Pan with Grates - INTERNATIONAL (Part #9598)

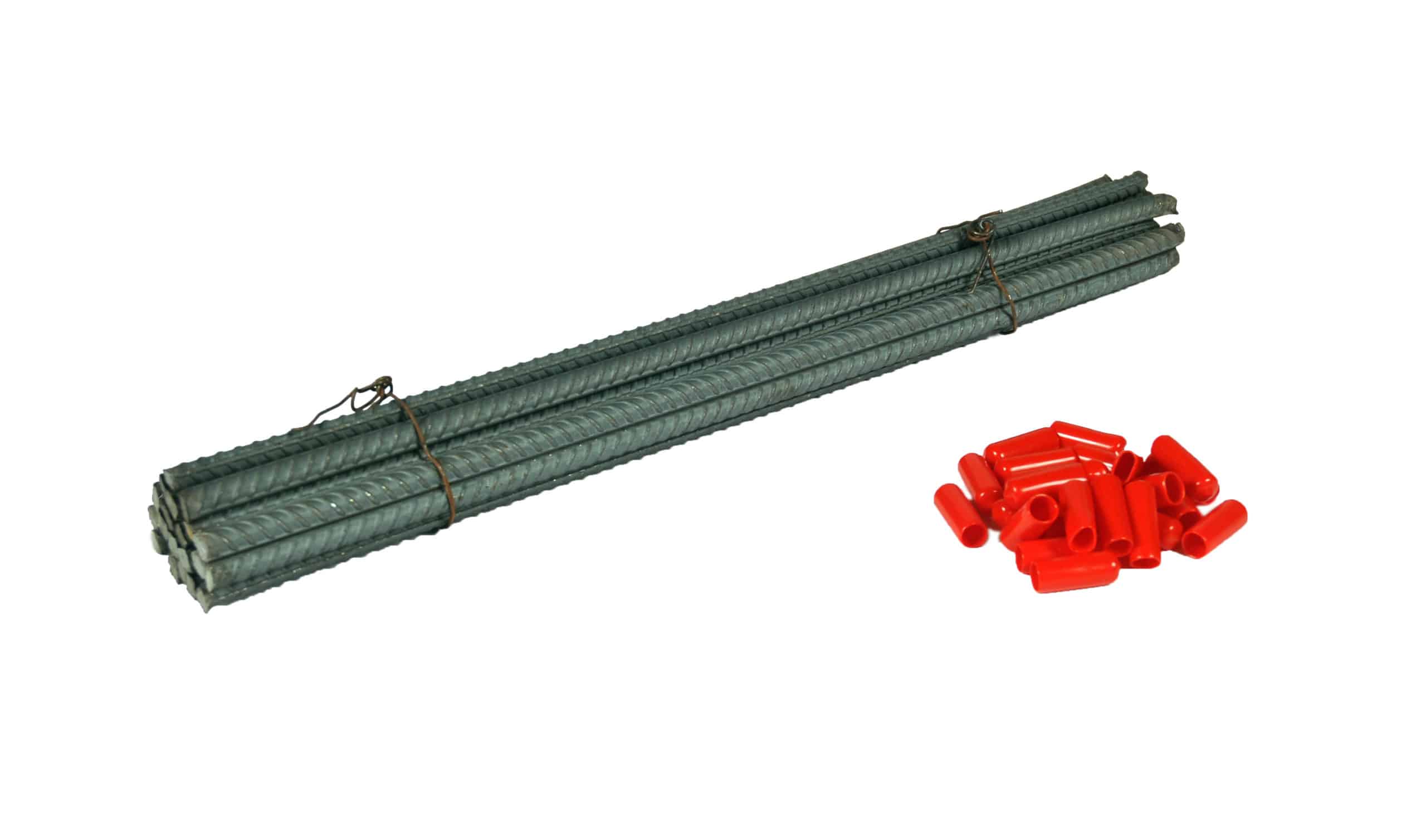

- UPC 808416095845 Ultra-Track Pan Rebar Fasteners With Protective Caps (Part #9584)

- UPC 808416095593 9559 - Ultra-Track Pan, 3" Drain Fitting 3" Diameter Drain Fitting for Below Grade Piping (Part #9559)

- UPC 808416095715 Ultra-Track Pan Grate Only For Center Pan - Left Grate (Part #9571)

- UPC 808416095739 Ultra-Spill Deck Plus Grate Only (Part #9573)